Features

| MODEL | WHTec 130 | |

| HEAD | ||

| Work spindle diameter | mm | 130 |

| Work spindle speed range | 1/min | 10-4000 |

| Rated output of main motor S1 | Kw | 37/46 |

| Rated torque on spindle S1 | Nm | 3200 |

| COURSES | ||

| X – Transversal table | mm | 2000, 3000, 4000 |

| Y – Vertical head | mm | 1600, 2000, 2500 |

| Z – Longitudinal column | mm | 1600, 2000, 2500 |

| W – Axial | mm | 800 |

| TABLE | ||

| Table dimensions | mm | 1800×1800, 1800×2200, 1800×2500 |

| Max. workpiece weight | Kg | 20000 |

| QUICK FEED | ||

| X, Y, Z | mm/min | 36000 |

| W | mm/min | 20000 |

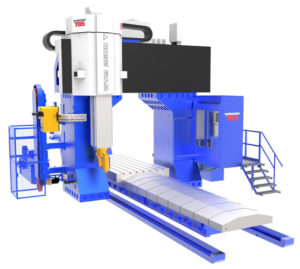

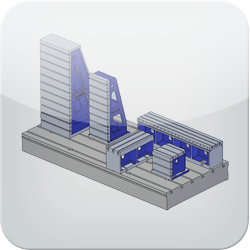

• The layout of these machining centres is based in a T configuration with a central chassis structure with linear guides that makes it more dynamic which makes these machines perfect for machining aeronautics parts, moulds or complex shapes that require high machining feed.

• The machining centre can reach 36 m/min because of the size of its linear guides with 3 m/seg2 acceleration. The rotation of the table can become another machining axis because it’s controlled by 2 motors in a master-slave system that makes possible high torque with high precision. It has a useful load capacity up to 25 Tn with a range of surfaces that can be adapted to every client’s needs.

• The flexibility of its configuration comes from the possibility of integrating several kinds of heads with the 130 diameter rod that rotates at 4000 RPM with 3200 Nm of torque.

• The heads can be loaded through an automatic head manipulator and the changes can integrated into machining processes. Among the available heads there are continuous positioning heads, heads with millesimal positioning every 0.001º x 0.001º, clevis type heads with electro-spindle and a wide variety of solutions to meet the needs of every client.