Features

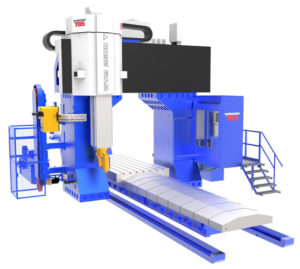

Centros de Mecanizado Tos Varnsdorf

Los centros de mecanizado son máquinas de alto rendimiento adecuadas para las operaciones más exigentes, con utilidades de mandrinado, roscado, torneado vertical y/o fresado. Adicionalmente tienen una amplia selección de accesorios según las necesidades de su empresa.

Comparativa de Centros de Mecanizado

|

| |||

|

Fotografía |  |  |  |

|

Tipo |

Tipo T |

Tipo T |

Tipo T |

|

Cabezal | |||

|

Ø Caña |

110 |

110 | 130 |

|

RPM |

4.000 |

6.000 |

4.000 |

|

Potencia Kw/Par S1 |

28 Kw /1200 Nm |

31 Kw / 1320 Nm |

45 Kw / 3200 Nm |

|

Salida caña |

- |

- |

800 |

|

Cursos | |||

|

Eje X (Transversal) |

1.500-2.000-2.500-3.000 |

1.500-2.000-2.500-3.000 |

3.000-4.000 |

|

Eje Y (Vertical) |

1.250-1.600-2.000 |

1.250-1.600 |

1.600-2.000-2.500 |

|

Eje Z (Columna) |

1.500-2.000-2.500 |

1.500-2.000-2.500 |

1.600-2.000-2.500 |

|

Mesa giratoria | |||

|

Superficie |

1250 x 1250, 1250 x 1600 |

1250 x 1250, 1250 x 1600 |

de 1.600 x 1.600 a 1.800 x 2.500 |

|

Capacidad |

6 Tn |

6 Tn |

10 Tn – 20 Tn |

|

Tipo |

Giro continuo, doble motor |

Giro continuo, doble motor |

Giro continuo, doble motor |

|

Torneado |

-- |

500 rpm Ø 1600 |

opcional |

|

| |||

|

Avances |

25 m/min |

40 m/min |

36 m/min |

|

Guías |

Guías lineales alta precisión |

Guías lineales alta precisión |

Guías lineales alta precisión |

|

| |||

|

Cabezal automático |

1º x 1º |

1º x 1º |

0,001º x 0,001º |

|

Plato de mandrinar |

Sí |

Sí |

Sí |

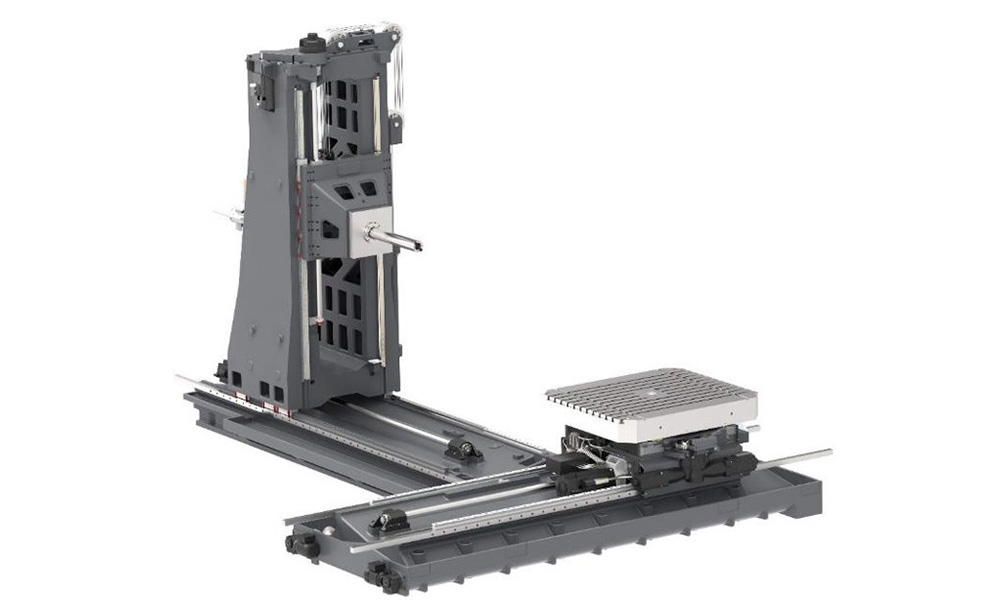

WHT 110

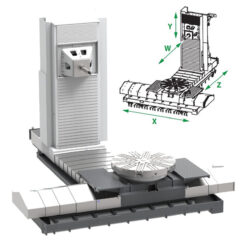

TOS Varnsdorf está renovando sus centros de mecanizado presentando unos modelos mucho más avanzados tecnológicamente, que permiten el fresado y torneado de las piezas complejas en un solo amarre y aporta una solución de alto nivel en el tamaño 2 x 2.

- Cabezal con caña/husillo integrada con recorrido 650 mm y 6000 rpm.

- Carga y descargar automática de cabezales de posicionamiento automático.

- Mesa de torneado con motor torque hasta 500 rpm y 1,6 metros de diámetro.

- Velocidad de posicionamiento 40 m/min

- Posibilidad de multiples palets para automatizar procesos de mecanizado complejos.

- Conectividad y aplicaciones de Industria 4.0

Estas características, un alto par de mecanizado tanto en el husillo como en los cabezales, y una amplia disponibilidad de distintos tipos de cabezales y opcionales, hacen que sea un centro ideal para moldistas, matriceros, fabricantes del sector oil & Gas y aeronáutico.

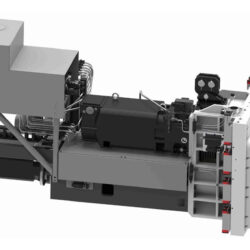

WHT 130

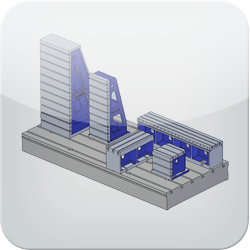

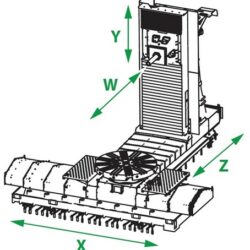

- El desarrollo de estos centros de mecanizado se basa en una configuración en T, con una estructura de bastidor central con guías lineales, que permiten una mayor dinámica que hacen de estas máquinas las ideales para el mecanizado de piezas aeronáuticas, moldes o formas complejas que requieran altos avances de mecanizado.

- El centro de mecanizado alcanza los 36 m/min gracias al dimensionamiento de sus guías lineales, con una aceleración de3 m/seg2 El giro de la mesa se convierte un eje más de mecanizado ya que está comandado por 2 motores en sistema master-slave que le permiten un alto par con una gran precisión. La capacidad de carga útil es de hasta 25 Tn con un rango de superficies adaptable a las necesidades de cada cliente.

- Su flexibilidad de configuración vienen dada por la posibilidad de integrar varios tipos de cabezales junto con la caña de diámetro 130 y que gira a 4.000 rpm, con un Par de 3.200 Nm.

- Los cabezales se pueden cargar a través de un manipulador automático de cabezales integrando su cambio dentro de los procesos de mecanizado.

Entre los cabezales se dispone de cabezales de posicionamiento continuo, de posicionamiento milesimal cada 0,001º x 0,001º, tipo horquilla con electromandrinos, y una amplia variedad de soluciones acordes a la necesidad de cada cliente.

Centros de Mecanizado Tos Varnsdorf

Los centros de mecanizado son máquinas de alto rendimiento adecuadas para las operaciones más exigentes, con utilidades de mandrinado, roscado, torneado vertical y/o fresado. Adicionalmente tienen una amplia selección de accesorios según las necesidades de su empresa.

Comparativa de Centros de Mecanizado

|

| |||

|

Fotografía |  |  |  |

|

Tipo |

Tipo T |

Tipo T |

Tipo T |

|

Cabezal | |||

|

Ø Caña |

110 |

110 | 130 |

|

RPM |

4.000 |

6.000 |

4.000 |

|

Potencia Kw/Par S1 |

28 Kw /1200 Nm |

31 Kw / 1320 Nm |

45 Kw / 3200 Nm |

|

Salida caña |

- |

- |

800 |

|

Cursos | |||

|

Eje X (Transversal) |

1.500-2.000-2.500-3.000 |

1.500-2.000-2.500-3.000 |

3.000-4.000 |

|

Eje Y (Vertical) |

1.250-1.600-2.000 |

1.250-1.600 |

1.600-2.000-2.500 |

|

Eje Z (Columna) |

1.500-2.000-2.500 |

1.500-2.000-2.500 |

1.600-2.000-2.500 |

|

Mesa giratoria | |||

|

Superficie |

1250 x 1250, 1250 x 1600 |

1250 x 1250, 1250 x 1600 |

de 1.600 x 1.600 a 1.800 x 2.500 |

|

Capacidad |

6 Tn |

6 Tn |

10 Tn – 20 Tn |

|

Tipo |

Giro continuo, doble motor |

Giro continuo, doble motor |

Giro continuo, doble motor |

|

Torneado |

-- |

500 rpm Ø 1600 |

opcional |

|

| |||

|

Avances |

25 m/min |

40 m/min |

36 m/min |

|

Guías |

Guías lineales alta precisión |

Guías lineales alta precisión |

Guías lineales alta precisión |

|

| |||

|

Cabezal automático |

1º x 1º |

1º x 1º |

0,001º x 0,001º |

|

Plato de mandrinar |

Sí |

Sí |

Sí |

WHT 110

TOS Varnsdorf está renovando sus centros de mecanizado presentando unos modelos mucho más avanzados tecnológicamente, que permiten el fresado y torneado de las piezas complejas en un solo amarre y aporta una solución de alto nivel en el tamaño 2 x 2.

- Cabezal con caña/husillo integrada con recorrido 650 mm y 6000 rpm.

- Carga y descargar automática de cabezales de posicionamiento automático.

- Mesa de torneado con motor torque hasta 500 rpm y 1,6 metros de diámetro.

- Velocidad de posicionamiento 40 m/min

- Posibilidad de multiples palets para automatizar procesos de mecanizado complejos.

- Conectividad y aplicaciones de Industria 4.0

Estas características, un alto par de mecanizado tanto en el husillo como en los cabezales, y una amplia disponibilidad de distintos tipos de cabezales y opcionales, hacen que sea un centro ideal para moldistas, matriceros, fabricantes del sector oil & Gas y aeronáutico.

WHT 130

- El desarrollo de estos centros de mecanizado se basa en una configuración en T, con una estructura de bastidor central con guías lineales, que permiten una mayor dinámica que hacen de estas máquinas las ideales para el mecanizado de piezas aeronáuticas, moldes o formas complejas que requieran altos avances de mecanizado.

- El centro de mecanizado alcanza los 36 m/min gracias al dimensionamiento de sus guías lineales, con una aceleración de3 m/seg2 El giro de la mesa se convierte un eje más de mecanizado ya que está comandado por 2 motores en sistema master-slave que le permiten un alto par con una gran precisión. La capacidad de carga útil es de hasta 25 Tn con un rango de superficies adaptable a las necesidades de cada cliente.

- Su flexibilidad de configuración vienen dada por la posibilidad de integrar varios tipos de cabezales junto con la caña de diámetro 130 y que gira a 4.000 rpm, con un Par de 3.200 Nm.

- Los cabezales se pueden cargar a través de un manipulador automático de cabezales integrando su cambio dentro de los procesos de mecanizado.

Entre los cabezales se dispone de cabezales de posicionamiento continuo, de posicionamiento milesimal cada 0,001º x 0,001º, tipo horquilla con electromandrinos, y una amplia variedad de soluciones acordes a la necesidad de cada cliente.