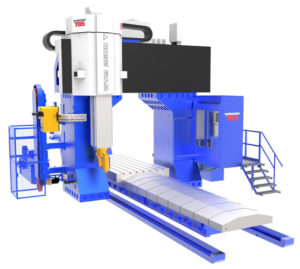

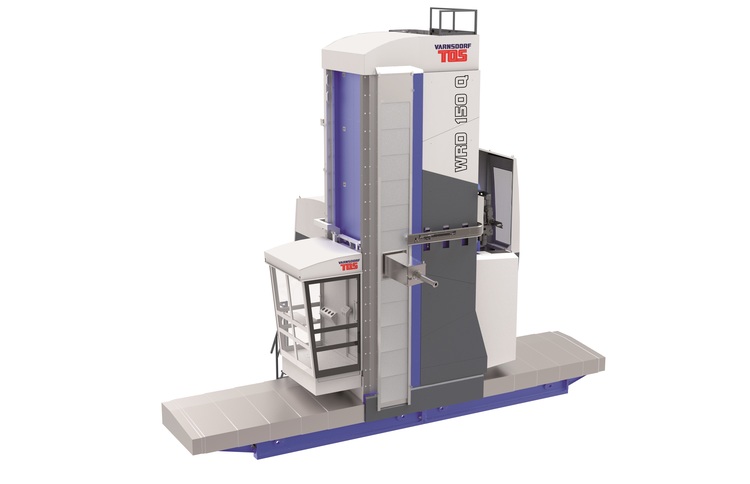

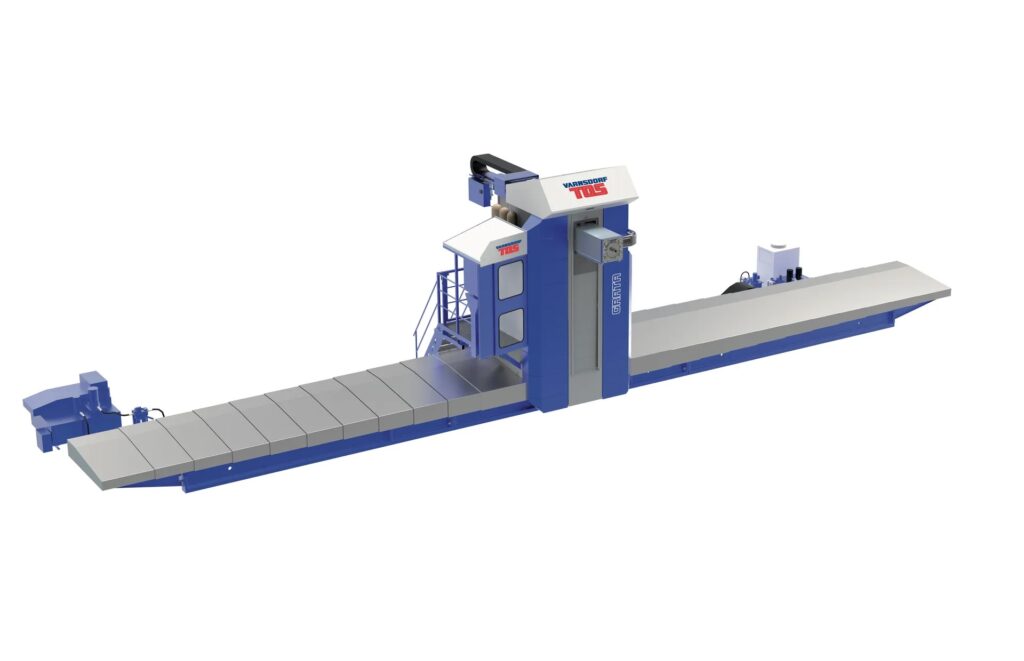

Mandrinadoras fresadoras de columna móvil Tos Varnsdorf

Las mandrinadoras de columna móvil de TOS Varnsdorf están diseñadas para la perforación, mandrinado, fresado y corte de roscas por coordenadas precisas. Se utilizan ampliamente en procesos complejos y en la producción en serie, garantizando alta precisión y eficiencia.

Son ideales para el mecanizado de piezas de gran volumen y peso, incluyendo estructuras tipo caja, placas y componentes con geometrías complejas. Permiten trabajar con fundición, acero y otros materiales mecanizables, asegurando acabados de calidad en sectores como la industria metalmecánica y la fabricación de grandes estructuras.

Además, las mandrinadoras de columna móvil de TOS Varnsdorf pueden equiparse con una amplia selección de accesorios, lo que amplía sus capacidades tecnológicas y las adapta a diversas necesidades de producción.

Comparativa de modelos de Mandrinadoras de columna móvil Tos Varnsdorf

|

|

WRD 13 | WRD 130/150 | WRD 170 | WRD 180 H | Grata |

|

Tipo |

De columna móvil con RAM y caña. |

De columna móvil con Ram y Caña. | De columna móvil con Ram y Caña. | De columna móvil con Ram y Caña. | Columna móvil con RAM sin caña |

|

Ø Caña |

130 |

130, 150, 160 | 170 | 160, 180, 200 |

Disponible solo como cabezal adicional. |

|

Recorrido caña |

650 |

800 | 1000 | 1200 |

-- |

|

RAM |

400 x 320 | 500 x 500 | 550 x 550 | 550 x 550 | 500 x 500 |

|

Recorrido RAM |

700 |

1200/1500 | 1500 | 1600 |

1500 |

|

Altura máxima (eje Y) |

3.000 |

6.000 | 6.000 | 6.000 |

3.000 |

|

Recorrido eje X |

Desde 3.200 hasta 20.200 |

Desde 5000 hasta 30.000 | Desde 5000 hasta 29.000 | Desde 5000 hasta 29.000 |

Desde 5000 hasta 30.000 |

|

Avances |

10-3000 |

10-3000, 10-2500 | 10-2200 | 10-3000, 10-2500, 10-2000 |

10-5000 |

|

Potencia cabezal (S1/S6) |

37/46 |

37/46, 51/65 | 71/88 | 74/101 |

37 |

|

Par husillo |

2535/3111 | 2535/3152, 2460/3138 | 3870/4800 | 6820, 11165, 13927 |

1584 |

|

Guías |

Guías lineales en la base y guías prismáticas con plástico antideslizante en la columna | Guías lineales | Guías lineales | Máquina hidrostática |

Guías lineales |

| Más info | Más info | Más info | Más info |